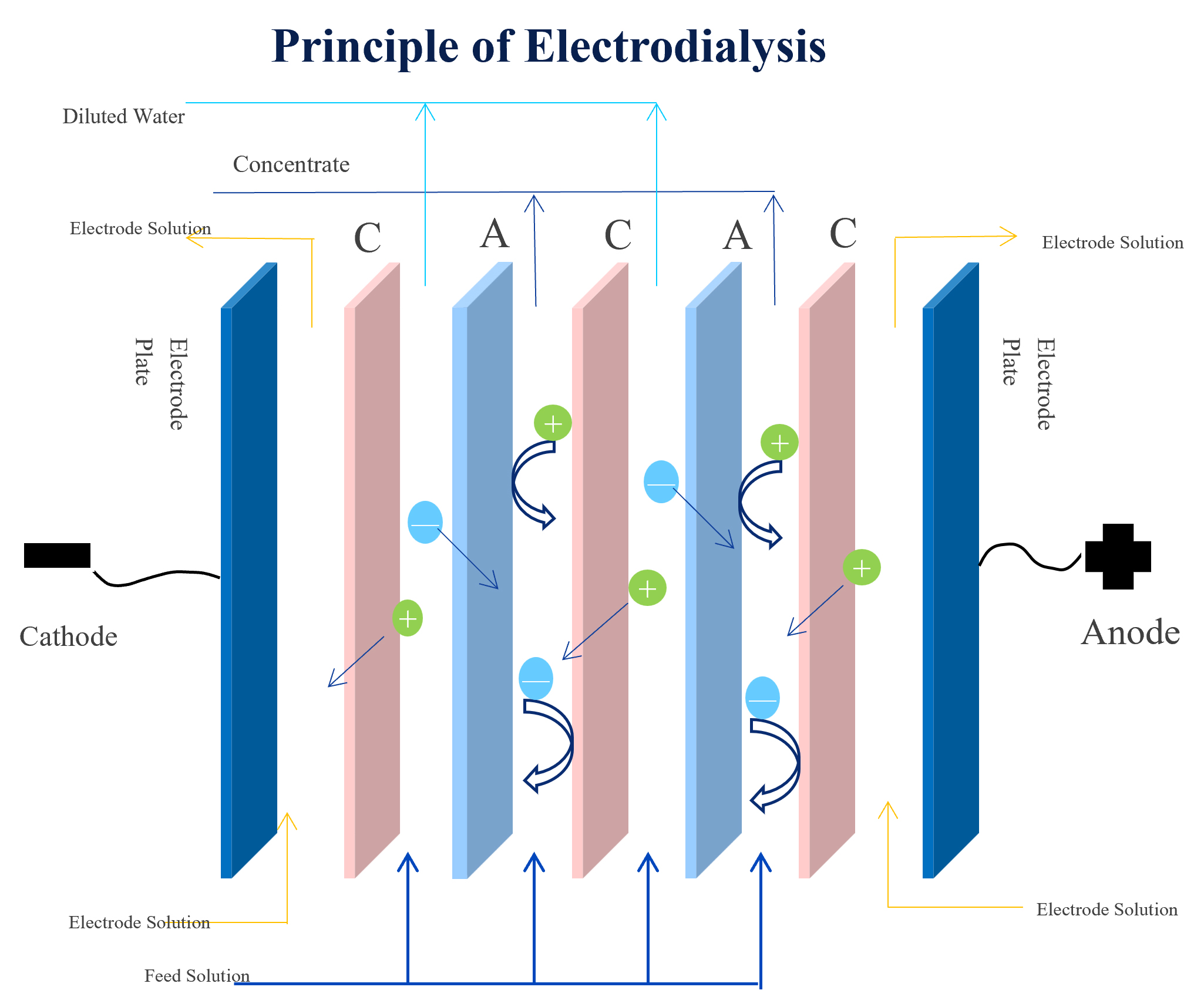

The electrodialyzer utilizes ion exchange membrane and DC electric field to selectively migrate ions of electrolyte in water, so as to achieve water desalination device, referred to as ED. Electrodialyzer consists of anode chamber, intermediate chamber and cathode chamber. Electrodialysis is essentially a desalination technology. The positive and negative ion exchange membranes in the electrodialysis device have selective permeability, and a salt-containing solution is placed in the device. Under the action of direct current, the positive and negative ions permeate the membrane and migrate to the cathode and anode respectively. Finally, in the intermediate chamber between the two membranes, the concentration of salt decreases, and the cathode and anode chambers are concentrated chambers. Electrodialysis methods can desalinate, concentrate, separate or prepare certain electrolytic products of electrolyte solutes or certain substances.

Principle of electrodialysis

The basic principle of electrodialysis desalination is to use the selective permeability of ion exchange membranes. The cation exchange membrane only allows cations to pass through, and blocks the passage of anions, and the anion exchange membrane only allows anions to pass through. Under the action of an external DC electric field, the ions in the water migrate in a direction, so that most of the ions in one channel of water migrate to the other channel of ionized water. To achieve the purpose of desalination of salt water.

Inverted Electrodialysis EDR

The EDR process refers to switching the polarity of the positive and negative electrodes at regular intervals (usually 15-20min) (frequently reversed), which can automatically clean the ion-exchange membrane and the dirt on the surface of the electrodes to ensure the quality and quantity of fresh water, and the ion-exchange membrane. Stable operation and minimum concentrated water discharge, EDR system is composed of three parts: electrodialysis body, rectifier and automatic reverse pole system.

The pole reverse operation procedure is as follows:

1. Change the polarity of the DC power supply electrode, so that the thick and thin chambers are interchanged, and the ion flow is reversed;

2. Change the water inlet and outlet valves, so that the water supply and drainage systems of the thick and thin chambers can be interchanged;

3. Continue 1-2 minutes after the polarity change, put the unqualified fresh water into the concentrated water system, and then the concentrated and fresh water will go their separate ways and resume normal operation

Applications Areas:

1, concentration and desalination2,Electrodialysis Separation of Inorganic Salts and Organic Matter.